Beginning Construction

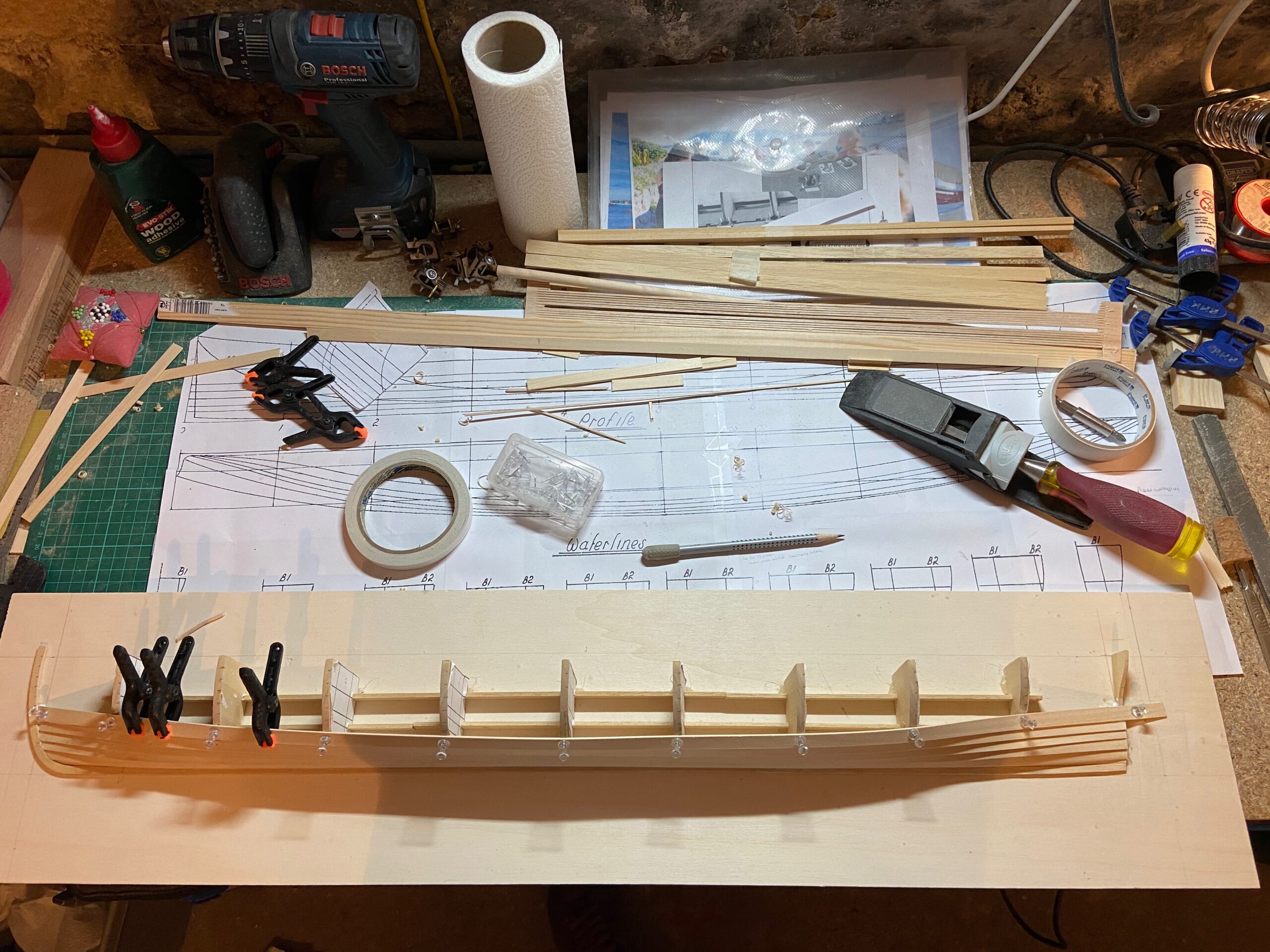

Construction of a Gig Economy gig model begins with laying the keel, prow, and transom on a birch plywood baseboard.

Nine 5mm Obeche ribs, cut to match the station measurements of the Treffry are then positioned and glued vertically to the baseboard ready to receive the hull planking.

Planking

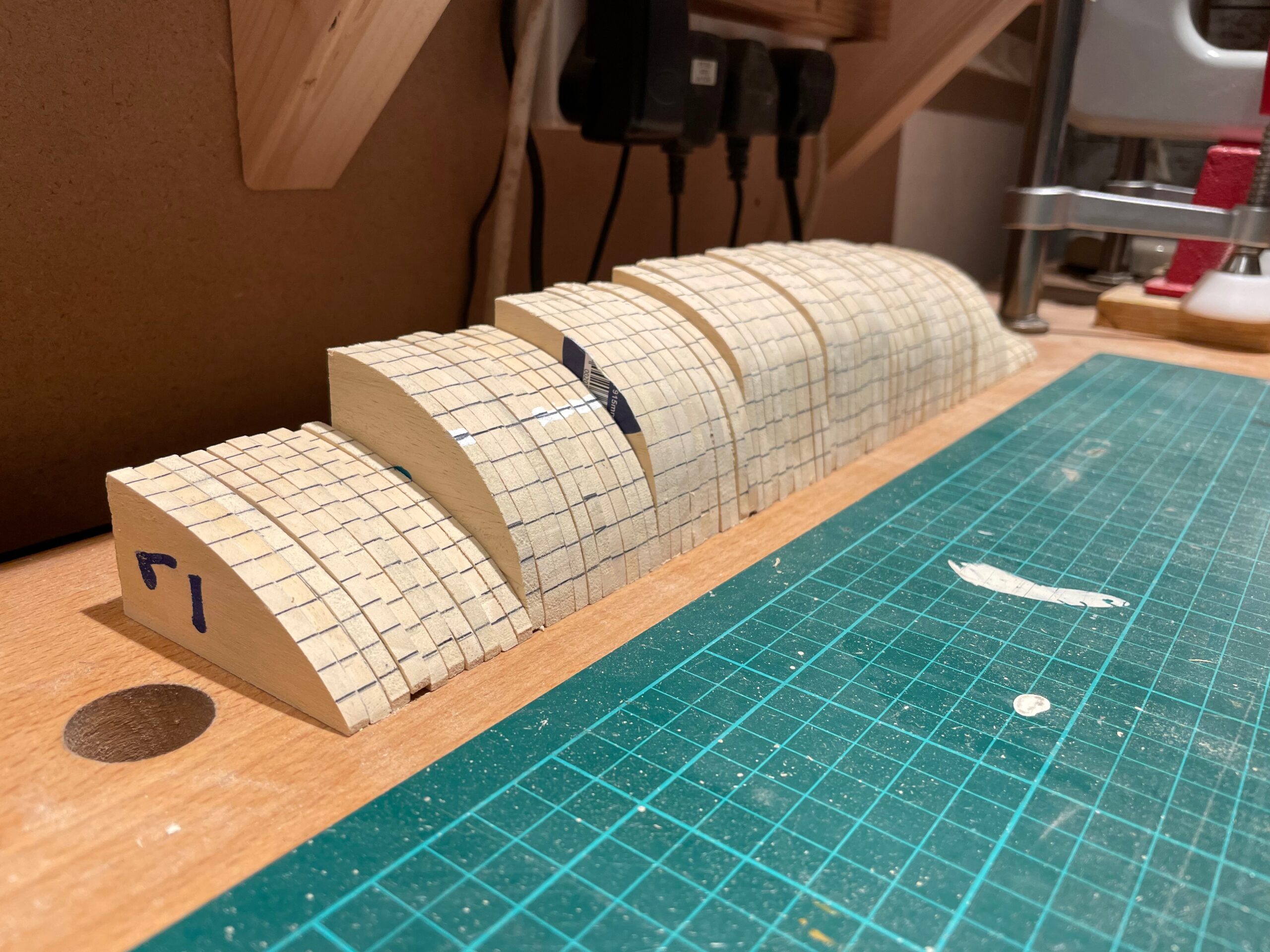

Lime hull planks are carefully selected for tightness of grain and flexibility before being carefully planed in preparation for fitting.

The 5 topmost planks – where the curvature is the most extreme – are notched with a scroll saw at regular intervals along the upper edge to ensure a buckle-free fit.

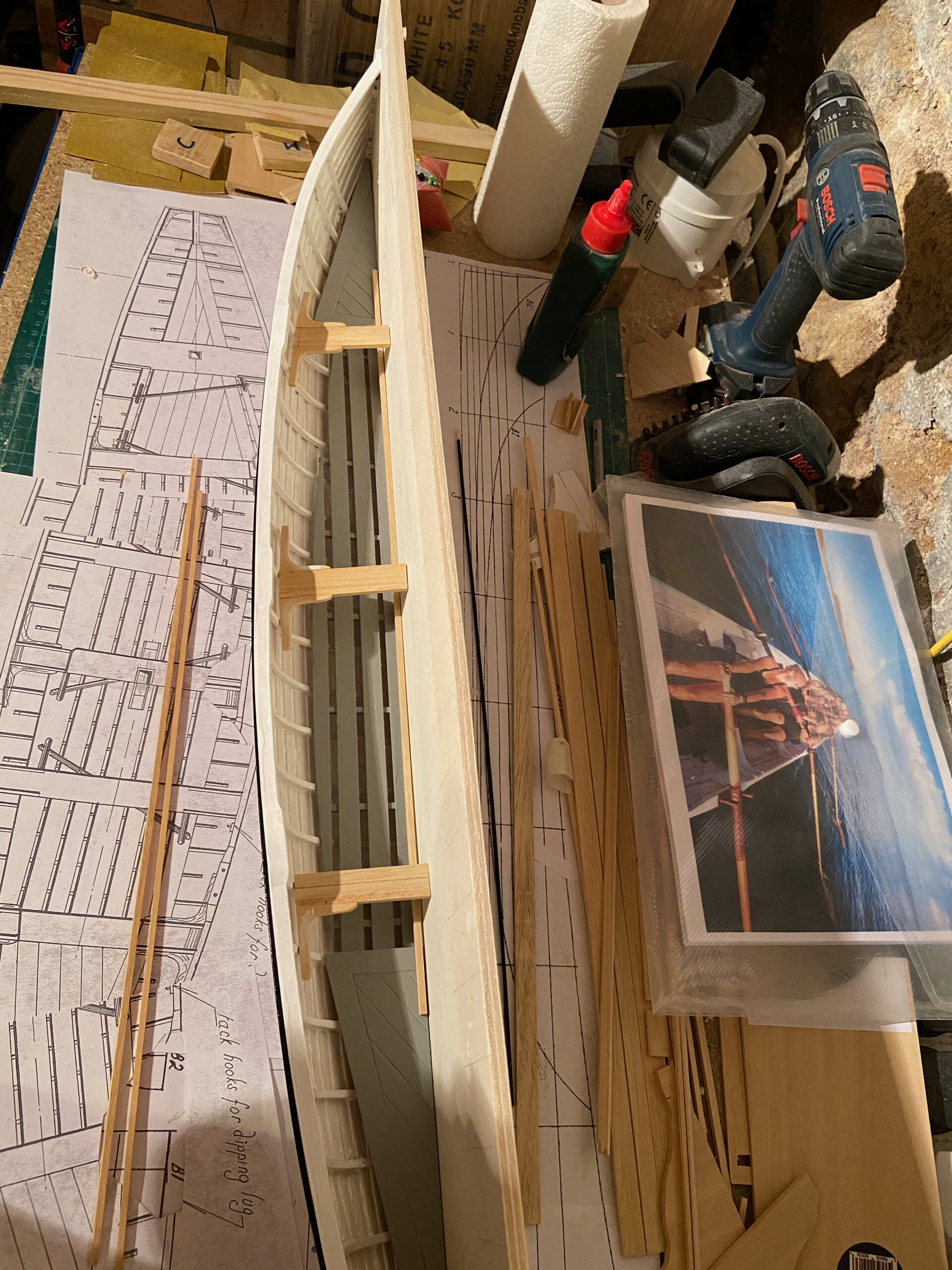

3x5mm lime gunwales are clamped into place all along the upper edge of the planking to complete the perfect hull, and the boat is then ribbed internally to match the original.

Adding Detail

Rowlock platforms are cut from planking timber and fitted to the gunwale.

Rudders and yokes are cut from 3mm lime sheet.

Internal fore and aft parquet floors are edged with mitred lime planks.

A rising is fitted to follow the planking of the hull and share the support the benches with a matching rising on the base board, carefully levelled.

Oars

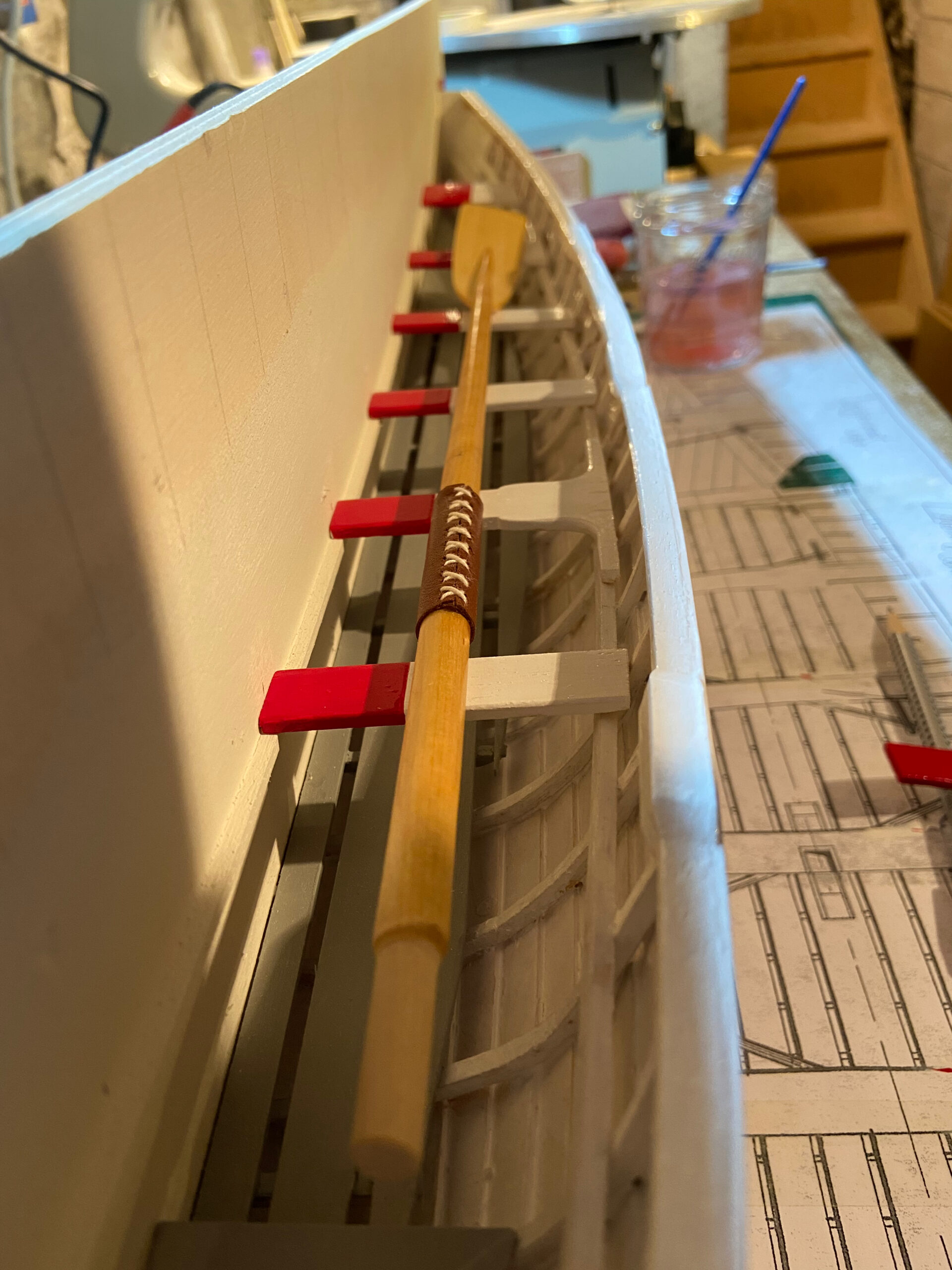

Oar shafts are turned from hardwood dowels, and the blades are constructed from a 5-layer layup of poplar veneers, cut and custom sculpted to shape.

Rowlock pads and oar collars are cut from goatskin leather and the collars are decoratively stitched into place.

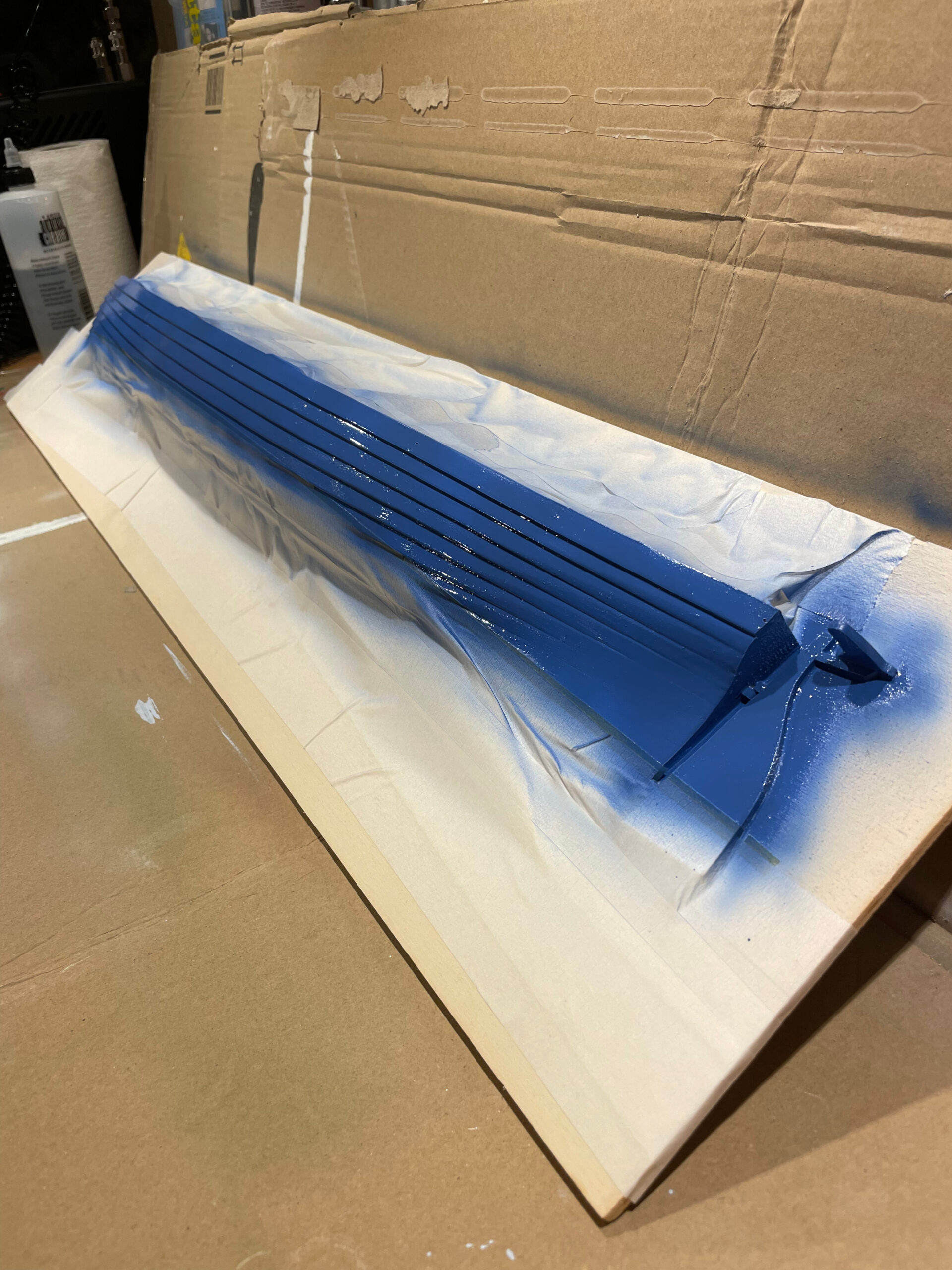

Painting

Gig Economy boats are airbrush finished in Fiddes hard wax oil and Billing boat paints according to the details of the livery chosen by the client.

Water lines are masked and painted with the help of a ceiling-mounted laser level to ensure perfect application.

Framing

Gig Economy frames are cut from solid English oak and stained and assembled in our workshop to order.

The Gig Economy is proud to use:

- Veritas planes, chisels and sharpening guides (www.veritastools.ca)

- Iwata airbrushes and compressors (www.iwata-airbrush.com)

- Amati strip woods (www.amatimodel.com)

- Billing Boat paints (www.billingboats.com)

- Fiddes wax oils (www.fiddes.co.uk)

- Sjöbergs workbenches (www.sjobergs.se)